Engineered Solutions

Engineered to Your Specifications

Over the years, we have invested in applications and manufacturing engineering. We also have CAD/CAM tools, metrology and lab resources that are unmatched in our field. In the beginning, we wanted to be more productive, allowing us to grow with best-in-class performance. Now, we have a full team, onsite or on call to help our customers be more productive.

Take advantage of our team and benefit from:

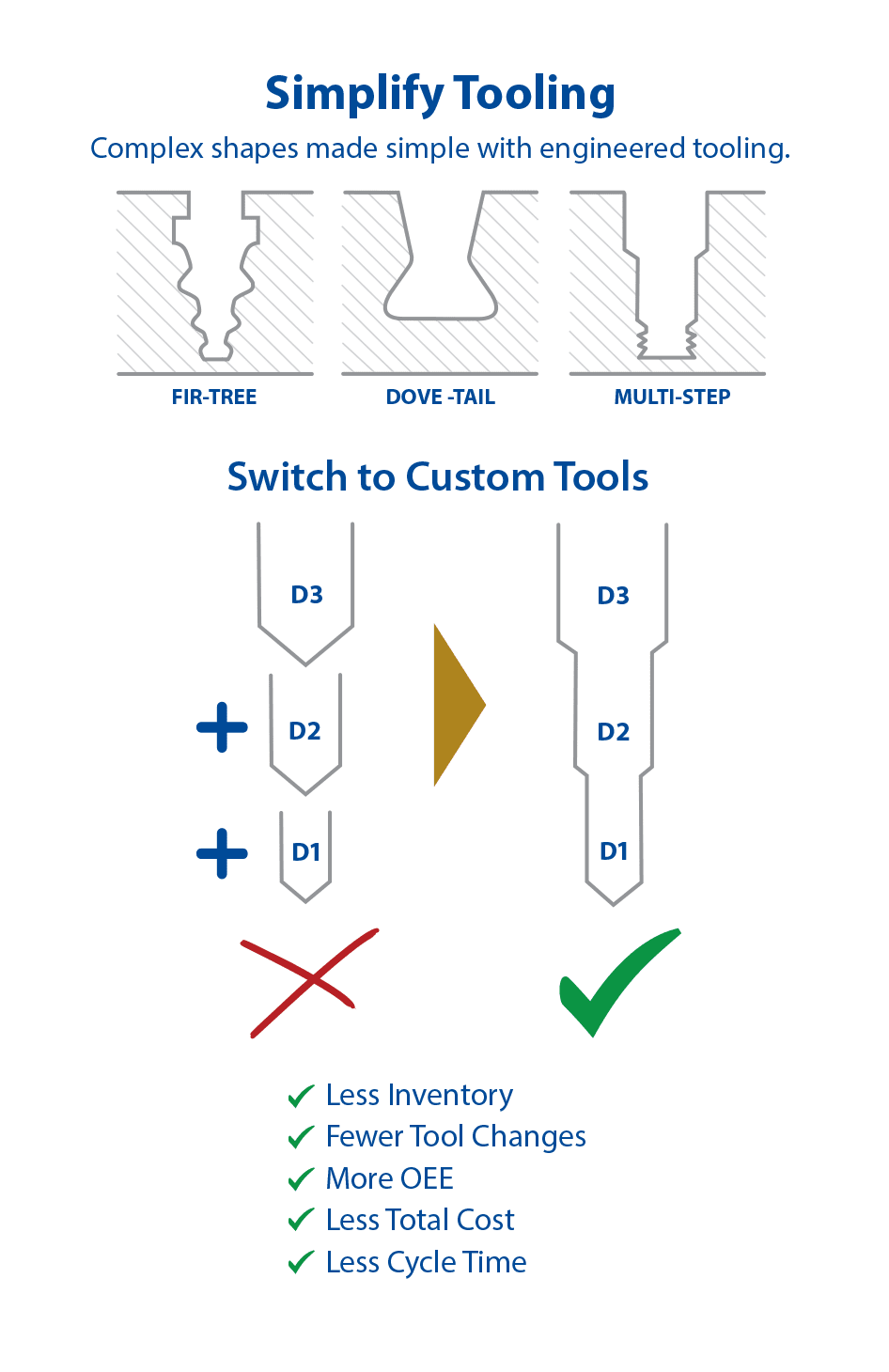

Solutions that Streamline Chipmaking Operations

Elimination of Multiple Tool Setups

Variance Reductions at Point of Cut

Technical Problem-Solving

Years of Experience Designing Material Specific Cutting Tools

At Tru-Edge, we make a point to visit our customers’ manufacturing facilities to gain first-hand knowledge of their operations and processes, enabling us to design the right tools with specific geometries to effectively machine parts.

Our engineers use real-time simulation software and integrated CAD/CAM programming, and have the responsibility for beginning-to-end project oversight. This attention to detail helps to ensure that a Tru-Edge tool provides optimized performance within your machining parameters.

By designing every tool with regrinding in mind, we manufacture tools that reduce the overall cost per part, not just tool cost. We are your tool life managers.

From our tooling concepts to your finished parts on the shop floor, Tru-Edge has the know-how to deliver savings that can increase your profits.

Looking at the case study, you can see our approach:

- How can we simplify tooling by combining operations?

- How can we design tools for manufacturing efficiency yet provide prolonged tool life?

- Can the tool be re-sharpened efficiently and provide 100% new tool performance?

- Are the tools designed to allow for a maximum number of regrinds?

In addition to engineering new tool designs, we can often modify your existing tools to produce

complex geometries that meet blueprint specifications. Applications related to aerospace,

automotive, food service, medical, mining, orthopedic instrument, tooling, and die & mold are

all candidates for these tool engineering services.

Regardless of your requirements, we have the engineering knowledge and design expertise to

meet demanding metal removal applications. Let us help you achieve your goals.