Quality

Quality Management System

In 2012, Tru-Edge achieved ISO 13485 and ISO 9001 certifications. The commitment to invest the time and acquire the resources necessary to gain these quality standards was driven by our customers. In 2018, we continued this commitment and obtained dual certifications to two new standards, ISO 13485:2016 and ISO 9001:2015.

Prior to our initial ISO audits, Tru–Edge developed a Critical to Quality (TE CTQ) process to steer our Quality Management System (TE QMS) and allow real–time process monitoring. Our skilled associates have always been responsible for controlling the quality of their work at their machines and following Standard Operating Procedures (TE SOP). In total, TE QMS drives capability for repeatability tool–after–tool, day–to–day, month–to–month, year–over–year.

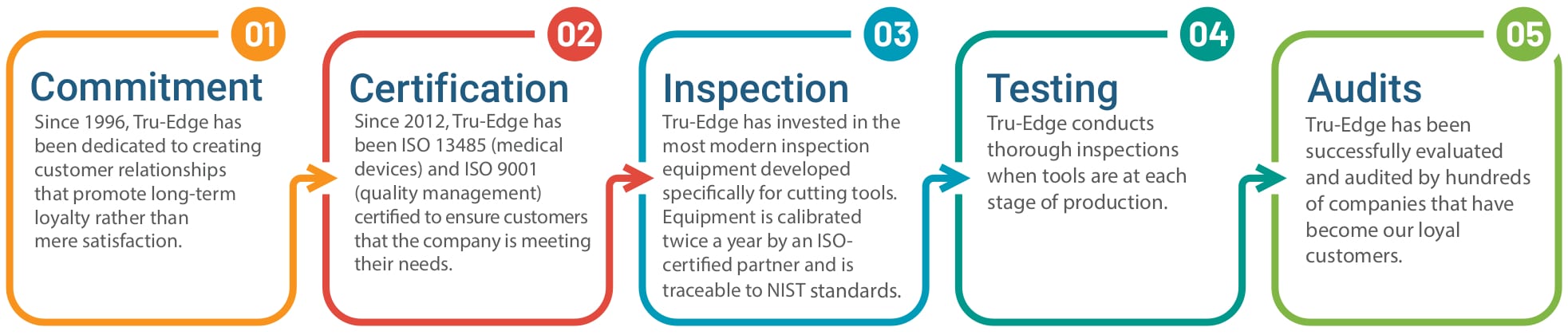

5 Steps to Excellence

Commitment

Since 1996, Tru-Edge has been dedicated to creating customer relationships that promote long-term loyalty rather than mere satisfaction.

Certification

Since 2012, Tru-Edge has been ISO 13485 (medical devices) and ISO 9001 (quality management) certified to ensure customers that the company is meeting their needs.

Inspection

Tru-Edge has invested in the most modern inspection equipment developed specifically for cutting tools. Equipment is calibrated twice a year by an ISO certified partner and is traceable to NIST standards.

Testing

Tru-Edge conducts thorough inspections when tools are at each stage of production.

Audits

Tru-Edge has been successfully evaluated and audited by hundreds of companies many of which have become our loyal customers.

Continuous improvement has been a mindset at our company since inception. We knew early on to compete with “mom and pop” shops meant producing a cutting tool that simply lasted longer and was more productive. Although we drive quality to the point of manufacture, there are inspections and testing at various stages of the production process. We maintain all inspection reports, and they are available upon request.

Some customers want to ensure their tooling meets their specifications when it leaves our facility. We offer specialized services to meet unique requirements. These services are set up through our sales and engineering teams and documented in customer specific TE CTQs. In several cases, we invested in state–of–the–art inspection and testing equipment to meet customer–driven quality requirements.

All our inspection equipment is calibrated twice a year by a certified ISO 17025 partner and is traceable to NIST standards.

Audits

Tru–Edge has been evaluated and audited by customers, as well as by a third–party registration body, and has earned ISO 9001:2015 and ISO 13485:2016 certifications.

We welcome the opportunity to show you our total quality system and process management capabilities.